-40%

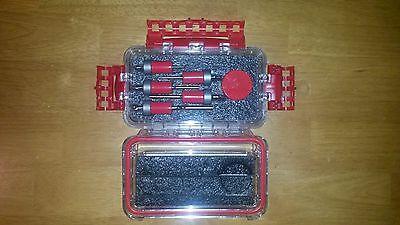

Rivet Removal Tool

$ 95.01

- Description

- Size Guide

Description

We've all heard the term "necessity is the mother of invention". In the case of the Loyd's Rivet Drill Guide it couldn't be closer to the truth. The idea behind this unique little kit of tools is to eliminate misdrilled rivets which directly effects the integrity of the hole that is to be reused. Also this tool keeps drill bits from "skating" off the heads of rivets and dancing across the skin, gouging the corrosion barrier on the skin and chewing up the customers paint job.There is a lot to be said for this tool because of the way it saves maintenance facilities money, time, materials, and in some cases, jobs. If you've been in the aviation industry any time at all, you should know that there is no such thing as a 0 fix, and you know how much time discussing how to fix a bad hole can be taken up. Aircraft delivery dates can get set back, because engineering had to get involved, an elaborate repair with straps and fillers and shims had to be fabricated, all because there wasn't enough ED after the discrepant hole cleaned up for the next oversize fastener. Strange how the little things can explode on you in this industry, even to seasoned mechanics. Basiclly misdrilled rivets create waste! The good news is, now there is a prevention. The cure is Loyd's Rivet Drill Guide. This tool is based on 43 years of experience in sheetmetal and structures. This kit was designed to be simple, and easy to use. The hard case even reflects a lot of thought, such as the FOD free closed cell charcoal foam, shadowed with the white foam underlay. The case is vapor and moisture tight, and will float. It also has a hinged lid with "O" ring seal and 3 over center cam latches. The kit comes with Boelube 70104. The theme of the kit is red, which makes it easy to spot if misplaced, even the vinyl handles on the drill guides are red in case they are dropped in the "bowels" of an aircraft. These drill guides can be used with threaded bits as well as straight jobber bits. These guides can be used with any 1/4" drill, 90 degree, 45 degree, snake drill, pancakes, etc. Because of their compact design they will work in tight areas such as inside of wings or under floors. The foot of each guide is designed to fit within the pitch of most all rivet patterns.

This Rivet Drill Guide tool is to remove rivets by drilling "dead center" every time, regardless of experience.

The Rivet Drill Guide eliminates misdrilled rivets which causes hole damage and costly rework.

The Rivet Drill Guide captures the protruding head of the rivet, allowing the foot of the guide to set on the surface around the rivet, which allows the drill bore to align perfectly over the head of the rivet. Hence, drilling straight, true, and center.

The Operator needs to know what size rivet that he or she is drilling out in order to select the applicable Rivet Drill Guide for the task.

These sets are designed one size under bore and hardened C1144 steel for long life. The drill lube is to ensure smooth minimal friction between the drill bit and the guide, cooling the bit, keeping it from galling, which aids in longer drill and guide life. Dip drill bit in lubricant at least once for every rivet.

These guides are easy to use. First select the appropriate guide for the rivet being drilled.

Use #41 drill bit and guide for 3/32 inch diameter rivets.

Use #31 drill bit and guide for 1/8 inch diameter rivets.

Use #21 drill bit and guide for 5/32 inch diameter rivets.

Use #13 drill bit and guide for 3/16 inch diameter rivets.

Use Letter "D" (.246) drill bit and guide for 1/4 inch diameter rivets.

Set conical recess over rivet head. Hold firmly with two fingers, making sure there is no movement from side to side. Dip drill bit in lube, insert drill into bore of guide and drill. Usually there is no need to drill much past the thickness of the rivet head in depth. After the head is drilled, the rivet can be punched out with little effort.

These guides allow you to drill straight and center every time. They are compact, easy to grip and easy to spot if dropped. They were designed to eliminate double drilled holes and drill bits "skating" off of rivets, and in that way they pay for themselves. We hope you discover what a valued asset these guides are. We hope you will notice your profits go up when your rework goes down. Excluding drill bits and lubricant, if you find within 30 days for any reason this set does not work for you, we will refund your money.